-

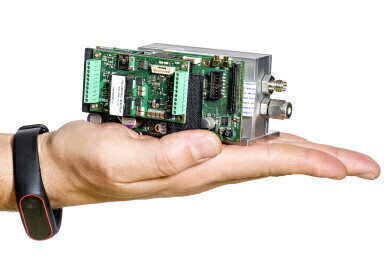

The module is very compact

The module is very compact -

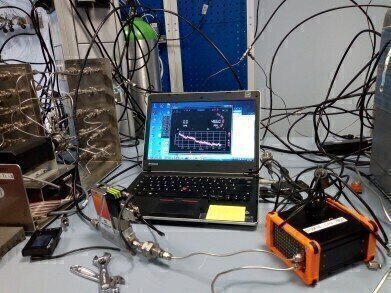

For clients who want to test out the module, a friendly software allows users to easily monitor gas concentrations (here, NO and NO2).

For clients who want to test out the module, a friendly software allows users to easily monitor gas concentrations (here, NO and NO2). -

Clients can first test the module in their R&D lab before OEM integration

Clients can first test the module in their R&D lab before OEM integration

Environmental Laboratory

Compact OEM gas analyser modules based on quantum cascade laser technology

Jan 16 2019

Existing laser-based gas detection technologies have reached a performance plateau. Indeed, traditional diodes do not lase in the mid-infrared fingerprint region where molecules absorb best and therefore are limited in sensitivity. NDIR techniques suffer from cross-interference and make it difficult to selectively detect a species. FTIR techniques can sometimes do the job but are rather expensive. Multi-pass cells don’t scale down in price with volume production and the mechanical moving parts don’t make it a robust solution for vibrating environments. Finally, the problem of cross-interference is not limited to laser-based techniques but can also be considered for other techniques like electro-chemical cells or paramagnetic techniques.

mirSense has developed a solution to meet these needs. After several years of development inside semi-conductor private labs, the mirSense company enters the market of gas analysis with a product innovation that combines high performance (sub ppm detection limits), small dimension (the size of a matchbox) and good cost-benefit ratio: the multiSense.

The multiSense combines two technological bricks: infrared quantum cascade lasers (QCL) and a heated photoacoustic cell. Both bricks have reached industrial maturity after several years of development.

QCL lasers are one of the few technologies able to emit in the mid-infrared (3µm to 12µm of wavelength) at ambient temperature and in a direct way. This wavelength range, well-known to spectroscopists, is the most significant range for the analysis of gas components because of the very strong absorption lines, with many molecules displaying a unique fingerprint. This range is well suited for trace detection of molecules.

Coupled to the lasers, the second technological brick, a heated photoacoustic cell, allows the detection of the spectral signature of the gases. By absorbing mid-infrared radiations, the gas will create a sound and emit various acoustic pressures that are detected by microphones. This system has no moving parts and is therefore more robust than multi-pass cells. It also has a great dynamic range with no saturation of the detector, allowing to measure from 1 to thousands of PPM for example.

Thanks to its know-how and by combining these two proprietary technologies, mirSense can offer detection performances of a few molecules amid one billion (10 ppb) in a very small format of a few cubic centimeters of volume, 10,000 times smaller than the current systems, for a cost inferior to current technologies.

The strategy of mirSense is not to sell an analyser to the end-users but rather to supply customised OEM modules for manufacturers of analysers that will integrate the mirSense modules inside their chassis.

Digital Edition

IET 34.2 March 2024

April 2024

Gas Detection - Biogas batch fermentation system for laboratory use with automatic gas analysis in real time Water/Wastewater - Upcycling sensors for sustainable nature management - Prist...

View all digital editions

Events

Apr 30 2024 Melbourne, Australia

Apr 30 2024 Birmingham, UK

May 03 2024 Seoul, South Korea

May 05 2024 Seville, Spain

May 06 2024 Minneapolis, MN, USA