Clothing

Independent Tests Confirm Fabric Permeation Resistance to Chemicals in Protective Clothing

Apr 24 2012

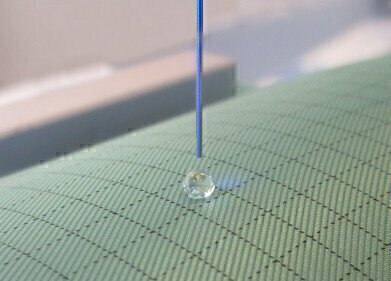

Recent tests conducted by an independent accredited laboratory show that Tyvek® L1431N fabric has a high barrier performance that provides excellent protection against liquid permeation. To most people all protective coveralls look the same and selecting the correct one to offer the best protection against liquid penetration and permeation can be a task in itself. And so to assess the barrier performance and therefore aid selection, permeation tests (according to EN ISO 6529 – Method A) were conducted to determine the breakthrough times of commonly used chemicals with

Tyvek®, MPF (Microporous Film) and SMS (Spunbond-Meltblown-Spunbond) – materials that are frequently used for type 4, 5, and 6 single-use chemical protective clothing.

To conduct the permeation test and determine the actual and normalised breakthrough times, 40% sodium hydroxide and 18% sulphuric acid, two commonly used chemicals in the industry, were selected. With a breakthrough time of over 480 minutes with two water-based inorganic chemicals, Tyvek® offered a higher barrier than the Microporous film, while SMS showed immediate breakthrough. Penetration tests were also conducted according to EN ISO 6530 standard and showed virtually no difference between the three materials, indicating the liquid barrier of the three materials seems to be of equal protection. However, this standard stipulates just one minute of exposure to the

hazardous substance, which is rarely the case in working conditions. When tested according to EN ISO 6529 - Method A, that determines the resistance of materials to permeation by liquids and gases, it was revealed that Tyvek® offers

long-term protection of up to eight hours. Tyvek® is an excellent material because the continuous, strong, high density polyethylene fibres do not shed and it does not contain additives or fillers. This smooth surface repels both liquids and particles, offering a very high chemical barrier in its category. Tyvek® is also extremely durable, highly resistant to tear and abrasion but still breathable and because of the smooth surface of the finished fabric it remains soft to touch and is extremely flexible, not restricting movement. To help customers make the right choice, DuPont has developed a series of videos featuring Professor Victor Tytonius, the cyber scientist who specialises in worker protection and chemical protective clothing and materials. Professor Tytonius carries out scientific experiments to reveal the performance of three non-woven structures – Tyvek®, MPF and SMS. The range of Tyvek® garments includes Tyvek® Industry, Tyvek® Classic and Classic Plus, Tyvek® Dual and most recently Tyvek® Labo.

Digital Edition

International Labmate 49.6 - Sept 2024

September 2024

Chromatography Articles - HPLC gradient validation using non-invasive flowmeters Mass Spectrometry & Spectroscopy Articles - From R&D to QC, making NMR accessible for everyone: Putting NMR...

View all digital editions

Events

Oct 30 2024 Birmingham, UK

Oct 30 2024 Manchester, UK

Nov 11 2024 Dusseldorf, Germany

Nov 12 2024 Cologne, Germany

Nov 12 2024 Tel Aviv, Israel