-

Figure 1: The BELSORP MAX X from Microtrac MRB.

Figure 1: The BELSORP MAX X from Microtrac MRB. -

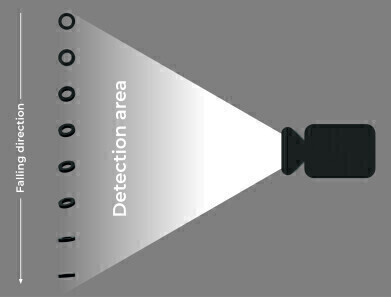

Figure 4: Measurement principle of the unique particle tracking technology.

Figure 4: Measurement principle of the unique particle tracking technology. -

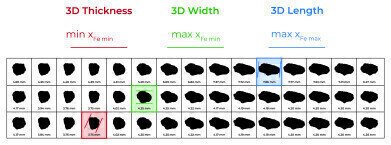

Figure 5: 3D particle tracking technology determines true length, width and thickness.

Figure 5: 3D particle tracking technology determines true length, width and thickness. -

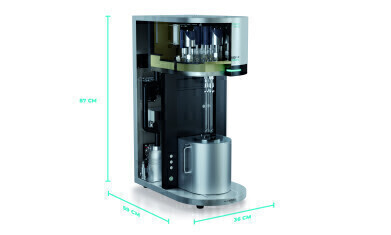

Figure 2: The high-end adsorption analyser BELSORP MAX X combines a small footprint with highest performance.

Figure 2: The high-end adsorption analyser BELSORP MAX X combines a small footprint with highest performance. -

Figure 3: The CAMSIZER has long been synonymous with precise and reliable DIA (Dynamic Image Analysis) measurement technology.

Figure 3: The CAMSIZER has long been synonymous with precise and reliable DIA (Dynamic Image Analysis) measurement technology.

Laboratory Products

Characterisation of Porous Particles: Surface Area, Pore Size and 3D Morphology

Feb 28 2023

Porous materials such as catalysts, activated carbon, zeolites, mesoporous silica, metal organic frameworks (MOFS) and many others are important for numerous applications in environmental protection, sustainable production, water and air cleaning, carbon capture, energy storage and generation, pharmaceuticals, food industry, etc.

Well-defined specific surfaces and tuned pore sizes down to the nanometer range are the typical characteristics that must be determined to guarantee high-performance materials.

Microtrac MRB's BELSORP MAX X (Figure 1) is the latest model in the BELSORP MAX series, featuring a lighter and more compact design. This high-precision gas/vapour adsorption analyser can measure up to four samples over a wide range of pressures and temperatures. BELSORP MAX X covers a wide range of analysis capabilities from specific surface area, pore size distribution, gas, and vapour adsorption to chemisorption.

Combining high-precision pressure transducers (133.3 kPa, 1.333 kPa, and 0.0133 kPa, optional High Pressure 1 MPa) with hard-sealing pneumatic valves and metal gaskets, the analyser has superior technology to minimise gas leakage and enable ultimate vacuum levels. Temperature in the BELSORP MAX X is carefully controlled using state-of-the-art technology, from the heated manifold block (50°C, optional 80°C) and air bath to the sample, while electropolished gas/vapor lines prevent surface wetting and corrosion.

In addition, the new BELCONTROL operation software facilitates understanding of the structure and durability of materials through cyclical stability analysis, improves measurement and maintenance efficiency, and sends measurement results via email - all resulting in maximised sample throughput. BELMaster™ is the dedicated analysis software for advanced material evaluations. This product complies with ISO 9277, 15901-2 and 18852 standards and can be used for other various material morphologies such as moulded bodies, pellets, and fine powders as well as particles.

Belsorp Max X helps you to maximise your lab space by minimising the footprint (Figure 2). The required lab space is reduced by almost 50% compared to alternative products.

Detecting the real morphology of particles with the new CAMSIZER 3D

Improved processing of the above-mentioned porous particles or particles in general includes energy-saving conveying, optimised packaging, additive manufacturing and much more. Therefore, the morphology of particles must be measured as accurately as possible in terms of their actual width, thickness, length, and shape. The name CAMSIZER has long been synonymous with precise and reliable DIA (Dynamic Image Analysis) measurement technology. Of course, the CAMSIZER 3D (Figure 3) also offers the proven dual camera technology that enables precise analysis of fine particles, an extremely wide measuring range, and excellent compatibility of results with sieve analysis. Two high-resolution and high-speed cameras guarantee accurate size and shape analysis over the entire measuring range. The unique, patented 3D technology of the latest model provides more meaningful particle size results than could be obtained with the traditional 2D approach, targeting applications previously not possible with dynamic image analysis.

How it works

CAMSIZER 3D combines all the advantages of dynamic image analysis (ISO 13322-2) in a completely redesigned measuring system. The instrument utilises a vibrating conveyor, LED strobe backlighting, and powerful highspeed and high-resolution cameras to perform the measurements.

As the particles enter the sensing zone, they execute a completely random tumbling motion as they fall. During measurement, the particle stream passes by an ultra-bright LED area light source; the resulting shadow projections are recorded by a camera system.

Thanks to the extended field of view, each particle is analysed up to 30 times, showing different perspectives, making the actual three-dimensional particle morphology accessible for analysis (Figure 4).

This creates a track of individual images of the same particle showing different projections. The evaluation of this track provides the true width, thickness, and length of every object. This also increases the informative value of all shape parameters usually determined during image analysis, such as aspect ratio, circularity, convexity, compactness, symmetry, etc.

Identifying defective objects with improved shape analysis

The 3D method also allows to reliably detect defective particles deviating from the desired shape. To find broken or fused particles in a sample of spherical material, such as for fertilisers, or determine the correct length of extrudates, are further important applications for Camsizer 3D.

Digital Edition

ILM 49.5 July

July 2024

Chromatography Articles - Understanding PFAS: Analysis and Implications Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers LIMS - Essent...

View all digital editions

Events

Jul 28 2024 San Diego, CA USA

Jul 30 2024 Jakarta, Indonesia

Jul 31 2024 Chengdu, China

ACS National Meeting - Fall 2024

Aug 18 2024 Denver, CO, USA

Aug 25 2024 Copenhagen, Denmark

-(1)-(1).jpg)

24_06.jpg)