-

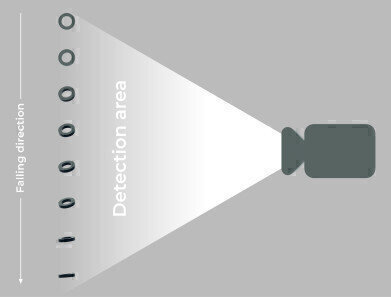

Measurement principle of the unique particle tracking technology.

Measurement principle of the unique particle tracking technology. -

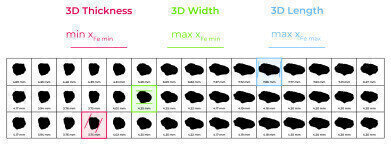

3D particle tracking technology determines true length, width and thickness.

3D particle tracking technology determines true length, width and thickness. -

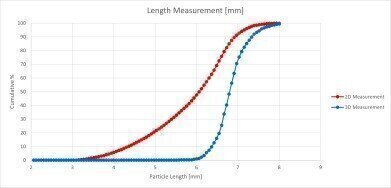

Analysis results of cylindrical extrudates 2D vs. 3D. Length distribution shows that the 2D result is ‘too short’: particle images don’t show the correct length due to random orientation.

Analysis results of cylindrical extrudates 2D vs. 3D. Length distribution shows that the 2D result is ‘too short’: particle images don’t show the correct length due to random orientation. -

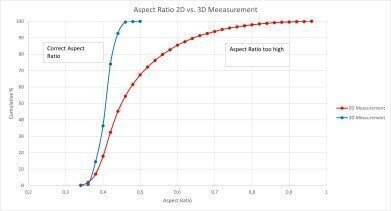

Analysis results of cylindrical extrudates 2D vs. 3D: The aspect ratio in the 3D measurement is relatively constant at 0.4 and in the 2D measurement it shifted to higher values.

Analysis results of cylindrical extrudates 2D vs. 3D: The aspect ratio in the 3D measurement is relatively constant at 0.4 and in the 2D measurement it shifted to higher values. -

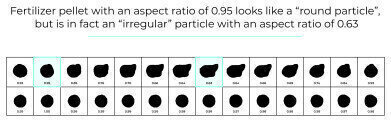

Upper track: Fertiliser pellet with an aspect ratio of 0.95 looks like a round particle, but in fact is an ‘irregular’ particle with aspect ratio of 0.63. Lower track: A truly round particle will show high aspect ratio on every image.

Upper track: Fertiliser pellet with an aspect ratio of 0.95 looks like a round particle, but in fact is an ‘irregular’ particle with aspect ratio of 0.63. Lower track: A truly round particle will show high aspect ratio on every image.

Laboratory Products

Particle Tracking reveals true morphology

Oct 11 2022

“Everything we see is a perspective, not the truth”. This quote is attributed to Roman Emperor Marcus Aurelius and although he probably had something else in mind, this somewhat describes an effect that can occur in particle size and shape measurement. Dynamic image analysis is now an established and proven method for the characterisation of bulk solids and users of this technique benefit from short analysis times and high sample throughput, because the method can detect and measure hundreds of thousands or even millions of particles within a few minutes. However, the images are snapshots, showing each particle in one of many possible perspectives, so the third dimension remains hidden. What works well enough for the size measurement of irregularly shaped particles and many natural products such as sand, crushed rocks, abrasives, or sugar, reaches its limits when materials of a certain predefined geometry need to be measured as precisely as possible in terms of real width, thickness, length, and shape.

The CAMSIZER 3D adds new perspectives to particle analysis, revealing the truth about the morphology of your sample at last!

How it works:

CAMSIZER 3D combines all the advantages of dynamic image analysis (ISO 13322-2) in a completely redesigned measuring system.

The instrument utilises a vibrating conveyor, LED strobe backlighting, and powerful highspeed and high-resolution cameras to perform the measurements.

As the particles enter the sensing zone, they execute a completely random tumbling motion as they fall.

During measurement, the particle stream passes by an ultra-bright LED area light source; the resulting shadow projections are recorded by a camera system.

Thanks to the large field of view and long drop distance, each particle is analysed up to 30 times, showing different perspectives, making the actual, three-dimensional particle morphology accessible for analysis.

This creates a track of individual images of the same particle showing different projections. The evaluation of this track provides the true width, thickness, and length of every object. This also increases the informative value of all shape parameters usually determined during image analysis, such as aspect ratio, circularity, convexity, compactness, symmetry, etc.

Length measurement of extrudates:

Extrudates like many plastic pellets or catalyst carrier rods have a defined base area given by design of the extruder and a variable length depending on the speed of extrusion and the setting of the cutting tool. The precise length measurement is an important quality marker and allows conclusions about the performance of the extruder. With the innovative 3D analysis method, the length of every particle projection of a 3D track is measured but only the largest of these numbers is used to calculate the length distribution. Thus, the correct length of every particle is determined, and the result is in perfect agreement with calliper measurement. Note that the length measured with the 2D-method, taking only one random image of every particle, is clearly ‘too short’.

Analysis results of cylindrical extrudates 2D vs. 3D. Length distribution shows that the 2D result is 'too short': particle images don’t show the correct length due to random orientation (left diagram). Accordingly, the aspect ratio in the 3D measurement is relatively constant at 0.4 and in the 2D measurement it shifted to higher values (right diagram).

Finding defective objects and improved shape analysis:

The 3D method also allows to reliably detect defective particles deviating from the desired shape: To find broken or fused particles in a sample of spherical material, one random view at each particle is also not sufficient, because the defective particle can accidentally show a circular projection and thus look like a flawless object.

Particle size and shape are important parameters for fertiliser quality. During granulation, the pellets will be shaped as nearly round particles. A non-optimal process will first be recognised by a change in particle shape, as the granulate will be ellipsoidal rather than spherical. Note that the diameter will stay the same and it won’t be reported in the standard sieve analysis. By measuring the roundness and aspect ratio, the CAMSIZER 3D will detect even smallest changes of the particle shape. Note that some of the non-round pellets in the 3D track show round projections. In 2D analysis these would be mistaken for 'Good product'. However, the additional images from the 3D track reveal the true nature of these particles. A truly round pellet will show high roundness or aspect ratio on every image of the track.

Conclusion: The CAMSIZER legacy expanded with patented 3D technology

The name CAMSIZER has long been synonymous with precise and reliable measuring technology. Of course, the CAMSIZER 3D also offers the proven dual camera technology which also enables the precise analysis of fine particles, an extremely wide measurement range as well as excellent compatibility of the results with sieve analysis. Two high-resolution and high-speed cameras guarantee accurate size and shape analysis over the entire measurement range. The unique, patented 3D technology enables more meaningful size results than ever before with the traditional 2D approach, opening applications that were not previously possible with dynamic image analysis.

Digital Edition

ILM 49.5 July

July 2024

Chromatography Articles - Understanding PFAS: Analysis and Implications Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers LIMS - Essent...

View all digital editions

Events

Jul 28 2024 San Diego, CA USA

Jul 30 2024 Jakarta, Indonesia

Jul 31 2024 Chengdu, China

ACS National Meeting - Fall 2024

Aug 18 2024 Denver, CO, USA

Aug 25 2024 Copenhagen, Denmark

-(1)-(1).jpg)

24_06.jpg)