Infrared / IR

QC and product screening of ink and paint with NIRS

Jan 12 2024

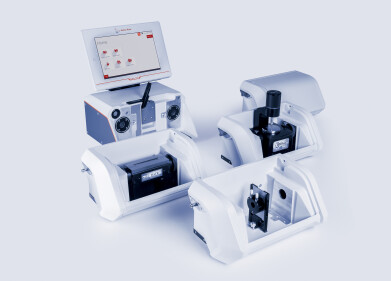

We encounter ink and paint on a daily basis. These materials are used for writing and printing, protection against the elements, aesthetic reasons, and so much more. Quality control (QC) of ink and paint can be done easily during all stages of production with near-infrared (NIR) spectroscopy. Using NIRS for QC and screening of ink and paint is more efficient and cost-effective than other analytical methods. NIR spectroscopy is an analytical technique that uses the interaction between light and matter to determine a sample’s chemical and physical parameters. In this situation, light is described by wavelength or wavenumbers rather than the applied energy. The interaction can be measured, e.g., with the Metrohm DS2500 Liquid Analyser, which generates NIR spectra. As NIRS is quite sensitive to the presence of some molecular functional groups, it is an ideal technique to quantify many chemical parameters. Non-volatile content, volatile organic compounds, dye content, surfactant content, and moisture can be measured simultaneously in paint or ink. Even the detection of physical parameters such as density and viscosity is possible with NIRS.

A single NIR spectrum contains all of this information, making near-infrared spectroscopy suitable for quick multi-parameter analysis.

Digital Edition

ILM 49.5 July

July 2024

Chromatography Articles - Understanding PFAS: Analysis and Implications Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers LIMS - Essent...

View all digital editions

Events

Jul 28 2024 San Diego, CA USA

Jul 30 2024 Jakarta, Indonesia

Jul 31 2024 Chengdu, China

ACS National Meeting - Fall 2024

Aug 18 2024 Denver, CO, USA

Aug 25 2024 Copenhagen, Denmark

24_06.jpg)