Laboratory Products

Enhanced Seal Performance for Freeze-Drying Applications

Jun 05 2012

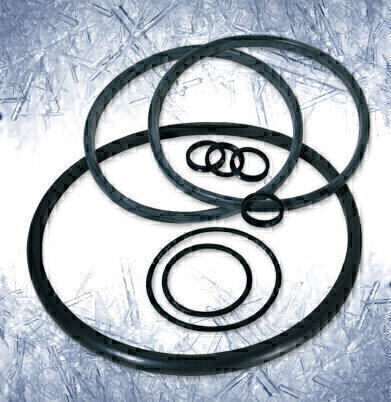

Freeze-drying processes can involve cycling temperatures in the range of - 20°C to +130°C, together with solvents and/or water under medium/high pressures. This combination of aggressive working conditions is conducive to the development of thermal stresses in the seals utilised for the freezer operation. These thermal stresses can also result in associated mechanical stresses leading to premature sealing failures due to cracking and blistering of the seal materials. Dupont™ Kalrez® 6230 perfluoroelastomer (FFKM) parts have been developed to meet such challenging sealing requirements, offering excellent steam cycling resistance up to 260°C.

In freeze-drying applications, the Kalrez® 6230 parts can also be used in a tri-clamp seal. This provides an extended performance in the presence of oxidising chemicals over competitive materials, while operating at high pressures and cycling temperatures between -20°C and +121°C.

Freeze-drying was actively developed for preserving serums being sent to Europe for the medical treatment of the war wounded during WWII. Without refrigeration, many serum supplies were spoiling before reaching the intended recipients. The commercial technique of freeze-drying enabled serum to be rendered chemically stable and so remain viable without having to be refrigerated. The process was also applied to penicillin and bone, and lyophilisation soon became recognised as an established technique for the preservation of biologicals. The process was also applied to penicillin and bone, and lyophilisation soon became recognised as an established technique for the preservation of biologicals. Freeze-drying is now used as a preservation processing technique for a wide variety of food and pharmaceutical products, including vaccines, diagnostic kits, viral or bacterial cultures, tissue analysis, and the production of synthetic skins.

Kalrez® 6230 parts are available in the UK from Dichtomatik Ltd, an authorised UK distributor for Dupont™ Kalrez® products. They are compliant with the United States Food and Drug Administration’s regulations and with the United States Pharmacopeia Class V1 (USP Class V1). They reduce extractables from sealing materials to trace levels, as well as offering a wide range of enhanced performance and endurance capabilities.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)