-

Precision for the laboratory: analytical balances and microscopes are among the wide range of product groups marketed by the oldest precision balance manufacturer in Germany today.

Precision for the laboratory: analytical balances and microscopes are among the wide range of product groups marketed by the oldest precision balance manufacturer in Germany today. -

On the path to growth: in 2021 KERN built a new modern office building at the company headquarters in Balingen, Germany. In the background is the high-bay warehouse, built in 2014.

On the path to growth: in 2021 KERN built a new modern office building at the company headquarters in Balingen, Germany. In the background is the high-bay warehouse, built in 2014. -

The passage of time: today, Albert Sauter, Managing Director of KERN & SOHN GmbH, is focusing on networkable products which can be adapted to meet individual needs as well as specialised software.

The passage of time: today, Albert Sauter, Managing Director of KERN & SOHN GmbH, is focusing on networkable products which can be adapted to meet individual needs as well as specialised software. -

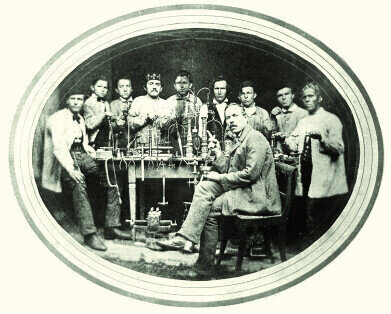

Mass-produced precision balances: company founder Gottlieb Kern (front) with workshop staff in the 1860s.

Mass-produced precision balances: company founder Gottlieb Kern (front) with workshop staff in the 1860s.

Balances

Precision balances and software into the eighth generation

Mar 08 2024

From analytical balances through to moisture analysers and on to fluorescence microscopes: Today, KERN & SOHN offers over 5,000 products to its customers in the laboratory, medical and industrial sectors. As the oldest precision balance manufacturer in Germany – probably even the world – the company has only been able to hold its own through continuous further development and innovation over 180 years. You have to go back more than 250 years to find the origins.

A village blacksmith became a balance manufacturer

In 1769, in the tranquil setting of Onstmettingen in the Swabian Alps, the village blacksmith Jakob Sauter I forged a ground-breaking innovation: an automatic balance for tradesmen, where the weight can be read from a pointer. It is an invention by the village pastor, Philipp Matthäus Hahn. Jakob Sauter graded the scale and adjusted Hahn’s balance to the right weight. Every balance is a one-off and adapted to suit the customers’ requirements. Jakob Sauter I became the first balance manufacturer of the family. He never dreamt that his descendants would still be producing and selling balances over 250 years later.

How KERN got its name

In 1812 Simon Sauter took over the workshop from his father Jakob I. With three of his sons he dedicated himself to precision balance manufacture. It is almost a miracle that such precise balances were developed in a remote village, long before there was an industrial need. Tragically two of Simon Sauter’s sons died young. Auguste Sauter, the widow of the deceased Matthäus Sauter, married Gottlieb Kern. He not only became an attentive stepfather for her son Albert. Kern also came into the Sauter workshop and founded the brand name we know today.

Mass-produced precision balances

In 1863 KERN, with nine employees, was already a large company in Württemberg from a tax point of view. Serial production of precision balances began. When stepson Albert Sauter came into the business in 1870, the company name was changed to GOTTL. KERN & SOHN. The company – already one of the largest precision balance manufacturers in Germany – was known at home and abroad at this time. In spite of all the highs and lows in the following decades, KERN balance manufacturing has maintained a stable course – through to the present day.

The new generation

At the beginning of the new millennium, the eighth generation of KERN came into the business with Albert Sauter. The classic precision balance range was expanded in the subsequent years to include industrial balances and measuring devices for force, hardness and layer thickness. In 2008 medical balances were added and six years later, microscopes and refractometers.

“Only continuous innovation and further development, but also sustainable management will enable us to continue our company’s success story,” Managing Director Albert Sauter is convinced, “Currently, we are focusing on networkable products which can be adapted to meet individual needs, specialised software and our fully-automated high-bay warehouse.”

Digital and networked

According to Sauter, today it is more and more common for measuring and weighing data to be transferred straight from the balance or measuring device to the computer for further processing. Weighing, counting and measuring results are shown in stock entries and on delivery notes. “We keep abreast of development through products which can be easily integrated into company networks,” explains Sauter. And the accompanying software is also becoming more and more important, in order to meet individual customer requirements.

Made to measure

The KERN range now covers 5,000 products and countless services. And yet often an individual, bespoke solution is called for. This is developed by KERN’s Customized Solution Service (CUSOS) department at the headquarters in Balingen/Southern Germany. In the development department, the company also makes sure that market feedback and ideas as well as individual customer requirements are fed back into product development.

Highly-automated, with the customer quickly

A 25-metre tall, fully-automated high-bay warehouse ensures a high level of availability and rapid dispatch of balances, microscopes and measuring devices all over the world. On a daily basis, 500 to 800 packages as well as 30 to 50 pallets leave the warehouse. Built in 2014, it will soon be at its limit. The plans for a second company location with another high-bay warehouse are already in full swing. “In addition we are planning branches in strategically important European markets,” revealed Sauter.

Sustainably into the next generation

A large photovoltaic system on the roof of the high-bay warehouse is now also saving KERN not only significant energy costs, but also considerably reducing the COâ‚‚ emission. “We are already heating and cooling our modern industrial buildings in a largely climate-neutral way using geothermal power. For packaging we are focusing on recyclable materials,” says Sauter, “In this way, step by step we are moving in the direction of a more sustainable future, as well as in the sense of moving our company story forward.”

Digital Edition

ILM 49.5 July

July 2024

Chromatography Articles - Understanding PFAS: Analysis and Implications Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers LIMS - Essent...

View all digital editions

Events

Jul 28 2024 San Diego, CA USA

Jul 30 2024 Jakarta, Indonesia

Jul 31 2024 Chengdu, China

ACS National Meeting - Fall 2024

Aug 18 2024 Denver, CO, USA

Aug 25 2024 Copenhagen, Denmark

24_06.jpg)