Laboratory Products

Low field NMR Instrument for particle characterisation and surface analysis of dispersions

Jul 08 2020

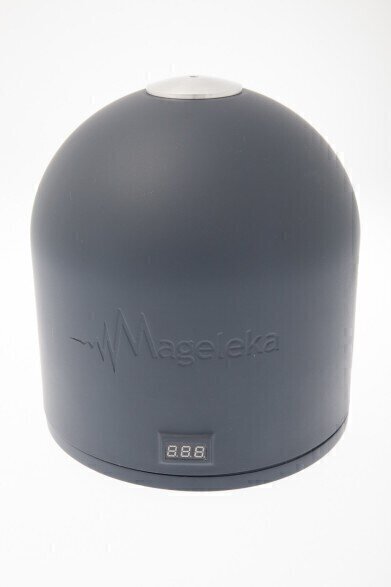

The Magnometer XRS a new instrument for particle characterisation and surface analysis of dispersions and colloids

The Mageleka Magnometer XRS is a new low-cost instrument for routine analysis of complex solid-liquid and liquid-liquid formulations using non-invasive technology based on NMR liquid relaxation.

In every industrial application a knowledge and understanding of the molecular structure and dynamics at the particle-liquid interface is critical to improving, or optimising, suspension and emulsion product performance at every stage from initial formulation to final manufacture. The Magnometer XRS provides direct information about the extent and nature of any particle-liquid interface of suspensions and emulsions in a matter of minutes without any sample preparation or sample destruction.

Measurements with the Magnometer are simple and easy, the sample is placed into a small sample tube and then inserted into the MagnoPod©, the test sequence is then initiated and the result reported via the proprietary MagnoSoft© software in under 2 minutes. With an exceptionally wide concentration range of 0.01% to 90+%, together with small sample size, typically 0.1mL or less and with little or no sample preparation the Magnometer is perfect for routine analysis of particles suspended in solvents and melts regardless of shape and size. The software is based on a simple GUI concept and with no prior experience is required, the Magnometer is suitable for chemists, technicians or plant workers. The separate sampling assembly allows for remote/hazardous or glove box operation and an optional programmable temperature-controlled unit is ideal for environments where temperature stability is required. The technique is also non-destructive so perfect for long term studies.

Applications include batch-to-batch reproducibility in a manufacturing environment and raw materials control where speed of measurement and reliability are performance factors. For example, formulation development, kinetic processes, surfactant and competitive surfactant adsorption, aggregation and flocculation, sedimentation studies, presence of para- and ferro-magnetic impurities, oxygen and water content of solvents, molecular weight of polymers in solution* polymer and solvent viscosity and additive studies have all been shown and examples are described on our website www.mageleka.com. The Magnometer XRS can characterise dispersions and colloids made with any nanoparticle and is sensitive to both surface and solution chemical environments and adsorbing additives such as polymers and surfactants. The technique is simple to use and does not require sample preparation with most measurements performed in under two minutes.

Industries served include catalyst companies, pharmaceutical and personal health care providers, paints & pigments, ceramics and refractories, agro chemicals, cosmetics, batteries, electronics, nano medicine and graphene/graphene oxides.

For further information visit our web site or contact email for more information.

*by calibration

Digital Edition

ILM 49.5 July

July 2024

Chromatography Articles - Understanding PFAS: Analysis and Implications Mass Spectrometry & Spectroscopy Articles - MS detection of Alzheimer’s blood-based biomarkers LIMS - Essent...

View all digital editions

Events

Jul 28 2024 San Diego, CA USA

Jul 30 2024 Jakarta, Indonesia

Jul 31 2024 Chengdu, China

ACS National Meeting - Fall 2024

Aug 18 2024 Denver, CO, USA

Aug 25 2024 Copenhagen, Denmark

-(1)-(1).jpg)

24_06.jpg)