Laboratory Products

Aseptic Workstation Ideal for CAR-T, Gene and Cell Therapy Highlighted

May 14 2018

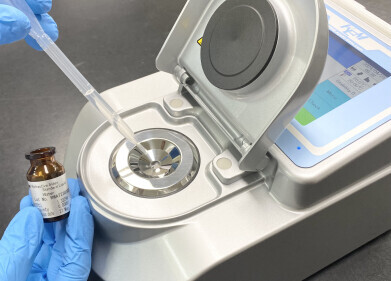

Bioquell UK Ltd has highlighted the suitability of its state-of-the-art Bioquell Qube aseptic workstation for the rapidly emerging CAR-T and gene and cell therapy sector. The isolator, which can be customised to suit the individual needs of cell therapy development companies, hospitals and service providers, is integrated with the company’s innovative Hydrogen Peroxide Vapor technology for rapid bio-decontamination, reduced risk and major cost benefits.

Bioquell’s cutting-edge isolator technology is ideal for the critical nature of CAR-T, gene and cell therapy, helping to reduce the potential risk of contamination by microorganisms or another patient’s cells through product handling and environmental exposure. With operators able to sit at the Qube work station, this transformative process can be carried out within a guaranteed safe and productive ISO 5/EU Grade A environment, providing an added level of protection from potentially costly and hazardous bio-contamination.

Bio-contamination found in critical zones within the cleanroom environment can affect the whole gene and cell therapy process and put successful patient outcomes at risk. This can lead to significant financial costs and impact operational resources. As a result, regulators are specifying Good Manufacturing Practice (GMP) biologics facilities to be more proactive in terms of microbial contamination control.

The Qube’s distinctive design far outperforms traditional isolators for decontamination in gene and cell therapy applications and provides an effective aseptic environment from research & development through to the manufacturing process. The system reduces risk and supports biologics manufacturing expansion, which potentially enables more patients to be treated at the same time.

Used with the Qube aseptic workstation, Bioquell’s Hydrogen Peroxide Vapor achieves more in less time by starting the decontamination cycle immediately. It eliminates the need to reach temperature or humidity levels to begin the process with the Hydrogen Peroxide Vapor providing a 6-log sporicidal kill over every exposed surface.

Both modular and adaptable, the Qube offers up to three chambers (two gloves in each) with optional material pass-throughs and Rapid Transfer Ports (RTP) designed to meet workflow needs. It enables decontamination of materials in one chamber whilst operatives work in another, and offers aseptic-hold retention for typically seven days depending on protocols. With most organisations starting with one system, Bioquell offers the option to add chambers at a later date to suit capacity requirements.

Each Qube hosts a chamber integrated with a Bioquell vaporiser module. Operators can choose to decontaminate within this workspace only or open connecting pathways to decontaminate adjacent chambers. With peace of mind that the Qube is implementing thorough decontamination, operators can focus on the job in hand.

Available with four levels of environmental monitoring for all viable and nonviable particle needs, the Qube has ability to incorporate the Merck Millipore Sigma Symbio Flex Sterility Pump and other distinctive options to ensure maximum efficiencies.

Constructed from tough and hard-wearing polypropylene, the Qube can be installed and validated within 12 weeks with minimal disruption to operation or workflow. It offers customised validated cycles providing ISO 5/EU Grade A environment with GMP compliance and 21-CFR Part 11 software available.

The Qube offers a wide range of advanced features including a password protected colour touchscreen control panel interface which allows easy navigation via intuitive icons. Cycles are validated and pre-programmed for quick and simple startup.

The Bioquell Qube is simple to install having been designed to easily fit through standard doorways. Plus it does not require ventilation, can switch between negative and positive pressure and uses a standard outlet so electrical work is rarely needed.

Optional accessories such as sterility test pumps, environmental monitoring and racking options are incorporated within the isolator.

Bioquell’s advanced isolator manufacturing process ensures product consistency and reduced production and delivery lead times meaning a bespoke solution can be supplied quickly.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK