Laboratory Products

Nano Spray Dryer - A World Novelty In Laboratory Scale

Apr 29 2010

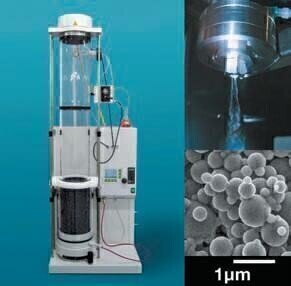

Büchi’s next generation instrument – the Nano Spray Dryer B-90 – revolutionises today’s spray drying possibilities with new innovative technology for unique particle generation down to the nanometer range from minimal sample quantities at high yields.

Spray drying is gaining greater attention in drug development, pharmaceutical formulation and particle design as a gentle, easy to control, continuous and scalable drying process to convert liquid formulations directly to dry powders.

The Nano Spray Dryer B-90 is especially designed to evaluate spray drying during the early stages of product development. The modular glass assembly and visible spray process allows quick and gentle drying of a whole variety of applications in small scale, ideal for feasibility studies in R&D laboratories to dry milligrams of powder.

The Nano Spray Dryer B-90 meets the needs in the pharmaceutical, biotech, medical, food ingredient, chemical, advanced material and nanotechnology. New application trends focus on effective formulation of complex pharmaceuticals and nanomaterial substances for novel drug delivery systems, like inhalable powder drugs. Typical applications are spray drying of aqueous or solvent based solutions, nanoemulsions, nanoparticle suspensions, structural transformations or nanoencapsulations.

The droplet generation is based on a piezoelectric driven actuator, vibrating a thin, perforated membrane in a small spray cap. The membrane features an array of micron-sized holes. The actuator is driven at ultrasonic frequency, causing the membrane to vibrate, ejecting millions of precisely sized droplets every second with very narrow droplet distribution. Different spray caps with 4.0, 5.5 and 7.0 micron hole sizes are available to achieve the droplet size between 5 to 25 microns precisely.

A unique heater technology based on porous metal foam provides a laminar gas flow in the drying section, optimal energy input guarantees fast heat-up times up to 120°C for very gentle drying of heatsensitive materials. The fine spray dried particles are separated by an electrostatic particle collector, a novel technology in laboratory scale. The electrostatic particle collector offers excellent particle recovery rates for nanoparticles of milligram sample amounts. It enables easy collection of small powder amounts of high value materials at high yields.

The integrated LCD display ensures easy process control. The PC software provides comprehensive data acquisition, storage and export capabilities. The glass visibility from spray head to particle collection and the very short set-up times allow easy cleaning and possibility for sterilisation.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)