-

ASCO 068 Series fluid isolation solenoid valves

ASCO 068 Series fluid isolation solenoid valves -

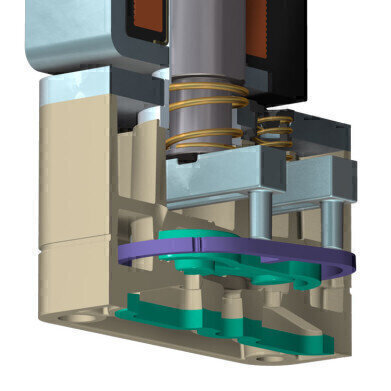

Flapper mechanism

Flapper mechanism

Laboratory Products

Emerson Fluid Isolation Solenoid Valves provide a high level of operational safety and reliability for Analytical and Diagnostic equipment

May 01 2019

Mechanical separation between the fluid handled and the valve’s control mechanism is one of the most essential features required for the sensitive applications of analytical and medical technology.

Flapper technology is among the most sophisticated and safest solutions for fluid isolation. Due to its specific characteristics, relatively high pressure rates are achieved – whilst the valve's pump effect is eliminated. Not only does it exclude particulate contamination caused by friction of moving parts, it also minimises heat transfer to the media, and even provides protection to the valve itself from harsh media.

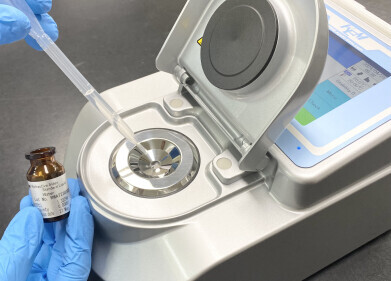

Typical fields of application are equipment with stringent sterility assurance and process safety requirements, such as analysers, blood and specimen purification equipment, chromatographs, dosing systems, gas mixers, micro-reactors, pipetting workstations etc.

Emerson offers 6 different fluid isolation technologies. They are designed to:

- exclude particulate contamination caused by friction of moving parts,

- minimise heat transfer from the electromagnetic control system into the fluid,

- ensure a high level of reliability of the solenoid valve when handling extremely aggressive fluids.

Flapper mechanism

Flapper technology builds upon a rocker mechanism. It’s special design allows significantly higher pressures to be achieved whilst the valve’s pump effect is eliminated.

Series 068 flapper valves

The ASCO 2/2 and 3/2 (16 and 22 mm) Series 068 fluid isolation solenoid valves with flapper mechanism, is suitable for use with neutral or aggressive liquids and gases. Fluid contamination is prevented by the fluid isolation design and the use of high-quality materials (PEEK and FFPM/FPM/EPDM).

The special flapper mechanism allows high pressures (up to 10 bar) to be achieved at large orifice sizes (0.8 mm to 4 mm). The use of a power-save connector lowers the holding power down to 2.5 Watts (or down to 1.5 Watts), thus minimising the heat transfer into the fluid.

Your benefits:

- Low power consumption (up to 1.5 watts with power-save connector)

- Low heat transfer into the fluid

- High pressure range

- No pump effect

- Low-volume internal cavity

- Good self-draining capability

- Easy-to-flush internal cavity reduces excess reagent

- Very good vacuum properties

- High-quality materials

- Long service life (tested in excess of 10 million cycles)

- Various electrical connection options

Emerson also offers an ASCO proportional controlled flapper valve with a tough PEEK material body that can withstand even the most aggressive media, considerably increasing its life span and ensuring a safe and accurate operation at all times. It has a pressure range of 0 to 4.5 bar, and a temperature range from 5ËšC to +50ËšC.

In addition it offers the following advantages:

- Proportional flow control with reliable fluid isolation

- High precision dosing of small volumes

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK