Laboratory Products

New Assembly System Ensures Precise Pressure for Protein Testing Kits

Dec 13 2011

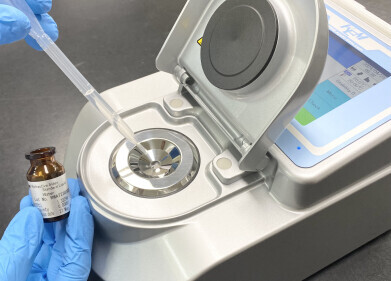

A custom built assembly system, developed and manufactured by Schmidt Technology, is being used by Albert Browne Ltd, a supplier of infection prevention products, to automate a critical process stage in the production of protein detection kits for use throughout the medical and healthcare sectors. The new system, based on Schmidt Technology’s latest 405 servo press, is providing extremely high levels of accuracy and applied force in a delicate application, while helping Albert Browne double productivity, improve working conditions and ensure product traceability. One of the company’s main product lines is the Ninhydrin Protein Detection Kit, used for detecting protein residues that may remain on surgical instruments after they have passed through a washer-disinfector. A key part of the kit is the supply of small test vials containing ninhydrin reagent in a gel form, which reacts to show the presence of amino acids, peptides and protein residues, plus vials of dried arginine.

Each vial measures 10mm in diameter and 150mm in length and is pre-filled with gel before an airtight stopper is inserted and the vials packed with other test items and instructions prior to shipping. The semi-automatic system developed by Schmidt incorporates a stainless steel rotary bowl-feeder, a pick and place mechanism, six station rotary table and a 405 servo press. Individual vials are hand loaded into each of the six location inserts on the rotary table. As the table indexes round, a stopper is first positioned by pneumatic grippers into the opening of each vial, before being presented to the press, which then forces the stopper home.

The press system developed by Schmidt uses dynamic closed loop force control to regulate precisely the force applied to each stopper as it is pressed into the vial, to within plus or minus 0.5N. The system is also capable of extremely fast ram speeds – of up to 200mm/sec – to improve cycle times, but can be instantly controlled to reduce speeds to just mm/sec over the final few millimetres of travel as each stopper is pushed home. Just as importantly, this can be achieved consistently, at a resolution of less than 2.4micron and a level of repeatability of under 10.0micron.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)