Laboratory Products

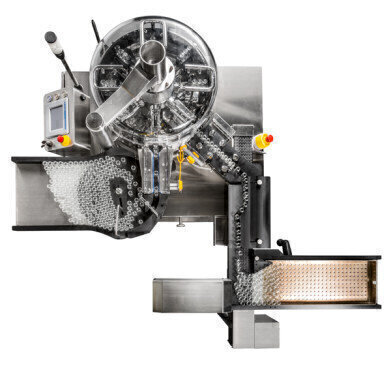

Automated Rotary Vial Washer

Oct 22 2018

SP PennTech announces the RW-500 rotary vial washer, a small automated system designed for low-to-medium output pharmaceutical and biotech applications.

The objective of vial washing is to remove particulate matter and microorganisms. Traditional vial washers employ many moving parts, and in particular, needles to direct wash water into the vials, which can lead to chipped vials and unwanted particulate matter. SP PennTech washers have only two moving parts inside the washing chamber, and do not use needles, minimising the chance of glassware damage and the possibility of an FDA 483 notice for a product containing unintended particulates.

Suitable for washing the full range of pharmaceutical vials from 2-100ml, the RW-500 combines effective vial washing with automatic tray loading enabling outputs of up to 100 vials/minute. Each vial format on the RW-500 has an HMI selected ‘recipe’ with specific settings for such variables as spraying time and indexing time. Water for injection may optionally be recycled, filtered and reused for early wash stages, and intermittent spraying further reduces water consumption.

The RW-500 rotary vial washer is designed as an efficient alternative to labour-intensive batch style vial washers. In comparison with in-line and batch washers, the RW-500 rotary washer design offers the benefits of minimal operator involvement, small footprint, optimised cleanliness and easy connection to infeed and outfeed in a production line.

All RW series washers are designed to be simple in operation, self-draining, with no moving parts in the washing area and have minimal maintenance requirements. An easily removed one-piece transparent polycarbonate cover permits easy visual verification of the flow of washing media.

Each vial neck format has its own dedicated set of change parts to optimise cleanliness, with a changeover easily manageable in under 15 minutes. All other changeover requirements, such as outfeed pusher movement and number of indexes per minute, are automatic and under PLC control.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

.jpg)