Laboratory Products

Next Generation Water Purification Unit Provides Purified Water for Life-Science Research

Jan 28 2020

A long-term relationship between Veolia Water Technologies UK (VWT UK) and one of its major pharmaceutical industry clients has led to the manufacturer updating its water purification equipment with one of VWT UK’s new generation ORIONTM units. To overcome specific access challenges within the Hertfordshire facility, the standard ORIONTM unit had to be specially modified.

A premier research and development service company, Pharmaron, specialises in a range of capabilities such as pharmacology, synthetic, medicinal and analytical chemistry, as well as chemical and pharmaceutical development within the life science industry.

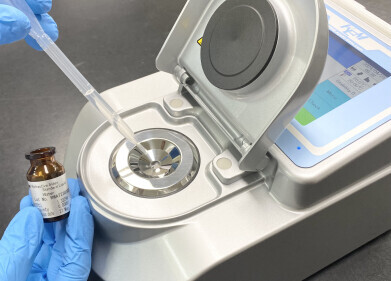

Due to the nature of the work Pharmaron carries out, it is vital that the company has a constant supply of pure water. VWT UK has been providing maintenance and support to the Pharmaron Hoddesdon site for water purification equipment since the early 2000s, ensuring an uninterrupted supply of purified water (USP/Ph Eur grade). This water is used for both cleaning equipment and as a raw material in the production of Active Pharmaceutical Ingredients.

The new ORIONTM 500 has replaced one of the three water purification units supplied by VWT UK in 2004, which had been operated in a ‘duty and back-up’ arrangement for many years. However, changes in output by the company had led to one ORIONTM unit being decommissioned and used for spares, prior to the new purchase being made as a planned upgrade.

VWT UK’s project manager and service engineers worked closely with Pharmaron’s own project team to sequence the delivery, installation and commissioning of the ORIONTM 500 during the Hoddesdon plant’s annual shut down period earlier this year: ensuring the changeover went as smoothly as possible.

Veolia Water Technologies UK’s Industrial Sales Manager, Kalpesh Shah, explained: “The original units had been craned into the building during its construction, but this option was no longer available and therefore the new assembly had to be configured to fit into the main goods lift. This was achieved by creating two skids.

“Over a very tight program, our engineers dismantled the original ORIONTM unit, installed the two new skids to form a single new ORIONTM 500 unit, commissioned and successfully validated the system.”

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

.jpg)