Laboratory Products

Trust a competent partner with an enviable track record

Dec 06 2022

The five brands of Verder Scientific (Carbolite Gero, Eltra, Microtrac MRB, QATM & Retsch) are a trusted supplier and partner for countless laboratories, scientific research institutions and manufacturing organisations around the globe.

Our companies employ over 1,000 people globally in 22 locations, provide high-quality solutions for individual customer requirements through the development of sophisticated, precise, and reliable equipment for sample preparation, heat treatment and analysis in quality and process control. These trusted solutions enable customers to effectively and reliably design processes, products, and services which are safe, efficient, and sustainable.

Frequently, multiple Verder Scientific brands will be employed by a single end-user. One of the best examples is in the field of additive manufacturing where:

- Carbolite Gero ovens and furnaces are used in MIM applications to debind (catalytically or thermally) and sinter the formed part.

- Eltra’s solutions are used for the quality control of metal powders. For example, during the sintering process, unwanted chemical elements like oxygen from air (corrosion) or hydrogen from moisture (hydrogen embrittlement) may degrade the quality of the product so these should be analysed.

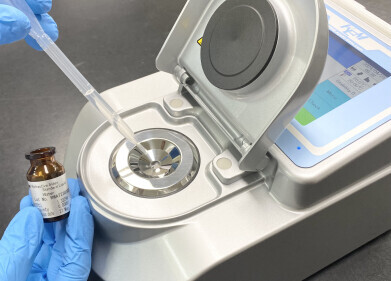

- Microtrac MRB offers two methods for particle characterisation of metal powders: Laser Diffraction and Dynamic Image Analysis. Both methods provide a size distribution, but only imaging methods also detect the particle shape which is crucial for the suitability of a powder for additive manufacturing

- QATM’s solutions are used after sintering for hardness testing in the quality control process and cutting, polishing, and etching machines allow for a perfect surface preparation as prerequisite for reliable micro-structural analysis.

- RETSCH instruments contribute to the recycling of raw materials with sieve shakers separating metal powder particles into fractions which are left after the 3D printing process – so that the fraction with the fine particles may be reused for the next printing process. In addition, their size reduction solutions are ideal for pulverising incorrect green bodies or hard metal parts produced during the MIM process so that the powder can be returned to the production process.

Additive Manufacturing is just one area where Verder Scientific solutions are frequently purchased together. Other areas include the ceramics industry, the cement industry, the steel and foundry industry and the energy production sector.

Finally, but crucially in recent years, Verder Scientific brands have been selected by many in the Battery Research sector who need to crush & sieve battery ‘ingredients’; homogenise cathode & anode materials; sinter those materials; perform elemental analysis on them and then determine their particle size & shape. This will ensure that the component materials are optimised for fast charging, maximum power holding and the safe discharge of energy. One outstanding project in this field is the project "Porous4App" at the Green Chemistry Centre of Excellence at the University of York, and the Bio Renewables Development Centre. It is developing a process to convert renewable plant-based resources into materials used in the production of batteries and catalysts, with the overall aim of replacing fossil fuel resources.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)