Laboratory Products

New Smart Infrared Loop Steriliser Allows Labs to Save on Plastic Waste

Nov 21 2019

WLD-TEC GmbH, the globally known specialists for safety laboratory gas burners and electrical annealing systems, are on a mission to reduce plastic waste in the lab caused by disposable inoculation loops. After testing the durability of stainless steel inoculation loops in combination with a safety laboratory gas burner and an infrared loop steriliser, WLD-TEC reported some startling results and statistics.

The test consisted of performing 30,000 annealings for a duration of 3 seconds each with only one 3 mm stainless steel inoculation loop. The results concluded that plastic waste from 30.000 disposable inoculation loops, plus their packaging, can be saved with one stainless steel inoculation loop used with an infrared loop steriliser, such as the SteriMax smart/basic.

In addition to this huge amount of plastic waste that is caused when using 30,000 disposable inoculation loops, approximately €2500 in costs will be incurred. As the price for the SteriMax smart/basic, including stainless steel inoculation loops, does not exceed €800, the instrument allows users to protect the environment as well as save a lot of money.

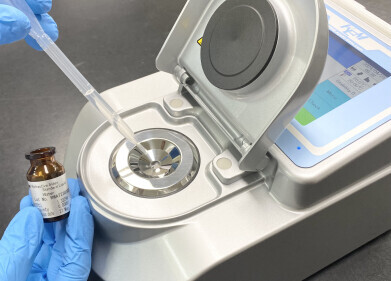

The SteriMax Smart from WLD-TEC provides high-speed annealing and sterilisation without gas flame and is ideal for all laboratories, anaerobic environments and safety cabinets.

This innovative steriliser uses specifically focused infrared light which generates an IR hotspot for sterilising inoculating loops at a temperature of 750° to 1000°C in only 5 to 10 seconds immediately and without any preheating.

Touchless IR-Sensor technology starts each sterilisation process automatically. Adjustable timers signal both the completion of sterilisation and cooling via the display and an audible signal. After that your inoculation loop is ready for use. Both timers can be adjusted and recalled individually and up to the second for two users by gently touching the panel.

’Thermocontrol’ is the key element for an efficient use of power. It allows for quick but smooth softstart of the infrared light, a short heating period and the re-use of residual heat for the next sterilisation process, which will be respectively shorter. Whenever you pause, your energy consumption and heat dissipation will pause as well.

Features include: instantly ready to work without any warm-up; Auto-Start through touchless IR-Sensor technology; adjustable sterilisation and cool-down timers for two users by front panel operation; annealing tube made of special quartz glass; very simple cleaning of the device and annealing tube; efficient use of energy and minimal heat dissipation thanks to Thermo Control; Cool -Touch housing made of stainless steel and safety glass.

For further information please click here.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK