Laboratory Products

Creating Liquid Mycotoxin Calibrants: A Behind-the-Scenes Look

May 25 2018

Reference materials, or calibrants describe substances or objects with one or more defined characteristic property value(s) that are used as a measure or as a benchmark for measurement methods. Given the importance of consumer safety for the food and feed industry, mycotoxin testing involves the use of reference materials in order to obtain accurate and reliable results.

Ever-present danger

Mycotoxins are naturally-occurring secondary fungal metabolites toxic to animals and humans. Mould fungi grow on the field and during storage. Found in almost all agricultural commodities worldwide, more than 380 mycotoxins have been identified and the toxicity of each substance varies greatly. The predetermined maximum permitted concentrations of various mycotoxins in vegetable raw materials such as grain, wheat, corn have forced commodity producers to examine their samples carefully in an analytical laboratory to be sure about the quality of their products.

Gravimetric preparation

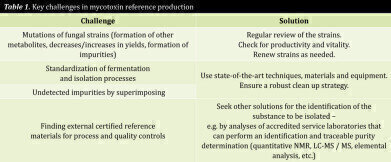

Frequently, a fungus that grows under optimal conditions can produce mycotoxins. In the lab, the story of a reference material begins with the attempt to adjust artificial growth conditions in order to obtain optimal mycotoxin yields. This includes the use of a suitable fungal genus, as every fungus produces its own characteristic pattern of metabolites that can number into the several hundreds. The maintenance of fungal strains for production is crucial. Their vitality and functionality are constantly being monitored, since this forms the basis of all activities for the reference material production processes. Moulds are living organisms that might mutate over time, or even degenerate and result in decreasing mycotoxin yields. New metabolites may form after a certain storage period, which can also influence the isolation process immensely. Strains must be renewed regularly in order to counteract mutations, impurities or other undesirable characteristics.

The first step, fermentation, hinges on making the lab environment literally as tasty as possible for the fungus to promote its growth. The optimal media also vary from strain to strain, so components such as salts and minerals are provided as a source of nutrients. The mould is allowed to grow for a certain time – anywhere from a few days to a few weeks – during which time the fungus metabolises its medium.

After completion of the fermentation and a careful control of the process the mycotoxin is extracted from the culture material using a suitable organic solvent. Depending on the molecular structure, these can be polar or non-polar organic solvents. During fermentation, moulds mostly produce impurities in addition to the toxin of interest, e.g. other metabolites, colourings, oils, etc.

The resulting crude extract often contains many impurities. During isolation or purification, the mycotoxin is brought step-by-step closer to the target purity of >98% through various chromatographic and preparative applications with different selectivity.

Some toxins have favourable molecular structures, and can be crystallised from a supersaturated solution of polar or apolar organic solvents. This happens, for example, by cooling the solution, by evaporating the crystallisation solvent or by mixing several solvents of different polarity. Other toxins may be rendered in crystalline, powdery form by freeze-drying. By crystallisation the purity of the toxin is thereby increased again until the target purity is obtained.

Quality control

HPLC, UV Photometer and HPLC-MS are used to determine/confirm the purity of the raw material produced. Depending on the toxin, this can be done for example by High Performance Liquid Chromatography in combination with Diode Array Detection, Fluorescence detection or similar, with UV Photometer (qualitative and quantitative analysis of the compound) or by High Performance liquid Chromatography combined with mass spectrometry detection. MS is particularly required for the above described determination of the isotopic purity (e.g. > 98% 13C atoms) of 13C isotope-labelled mycotoxins. Mycotoxin reference materials have a niche position on the market. Therefore, it is sometimes difficult to find comparative substances that are commercially available and can be used for process control during production and quality controls.

Delivery

After passing the final quality control, the solid mycotoxin is liquefied for use as a liquid mycotoxin reference material. The liquid calibrant solution is then bottled and a certificate of analysis is created, stating the property value and its uncertainty, which accompanies every single calibrant.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK