Laboratory Products

Collaboration Delivers Automated Nanoliter Hit-picking Platform

Jul 25 2011

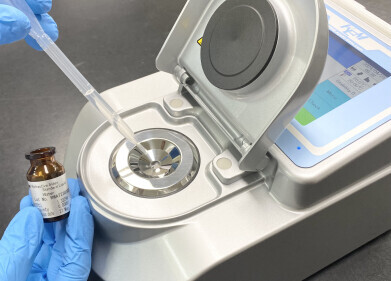

Thermo Fisher Scientific, Inc recently announced a new efficient, high-throughput platform for hit-picking of compounds for secondary screening.The solution, developed in collaboration with TTP LabTech for BioFocus, integrates the Thermo Scientific RapidStak microplate mover and the TTP LabTech mosquito® X1 nanolitre pipettor to provide exceptional high-speed plate handling and precision, low-volume sampling from highdensity formats. Millions of data points are generated by high-throughput screens, yet only a small percentage are identified as active compounds, requiring consolidation for further ‘hit to lead’ or secondary screening.

“Because hit rates are often very low, it is necessary to process high volumes of plates, and manual or semi-automated set-ups cannot deliver the throughput required,” said Hansjoerg Haas, Product Line Director, Laboratory Automation, Thermo Fisher Scientific. “We have worked with TTP LabTech to integrate the renowned mosquito and RapidStak technologies to develop a fully automated solution for BioFocus that offers true walkaway capabilities.”

“Hit-picking systems must be able to quickly and efficiently address individual wells in high-density format while avoiding cross contamination,” said Joby Jenkins, Product Manager, TTP LabTech. “Using disposable micropipettes, the mosquito X1 provides precision sampling from any individual well in any plate, and the accurate delivery of compounds in nanolitre volumes negates the need for a further dilution step prior to secondary screening.

“Coupling this technology with the Thermo Scientific automated microplate handler for rapid plate delivery and manipulation has enabled throughput to be significantly increased.”

The fully automated hit-picking platform is controlled by the mosquito CherryPicker software.

This will convert a CSV file of transfers (pick lists) from a laboratory information management system into an optimised protocol for the mosquito X1 and RapidStak before managing the run. Barcoded plates can be stacked in any order in the RapidStak, utilising unique buffer nest technology that allows for the high-speed, parallel processing of stacking and plate loading. As a plate is loaded, the barcode is read and the correct transfers for that plate are carried out. CherryPicker automatically optimises all mosquito protocols for efficient tip usage and optimal dispense heights, and, if required, it can also track the source plate volumes for subsequent reporting. Furthermore, a multi-dispense option can dispense into multiple wells or wells within multiple plates from a single aspiration, offering significant time saving benefits.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)