Laboratory Products

Rapid Evaluation of Critical Reactions Supporting Contract Research and Manufacturing

Sep 01 2020

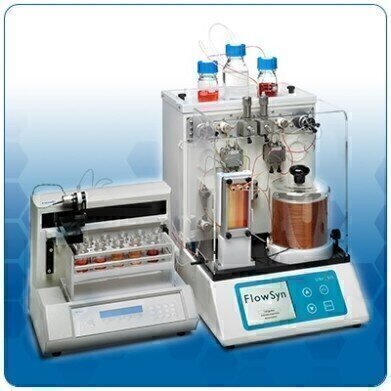

Uniqsis, in conjunction with their exclusive USA distributor, Sentinel Process Systems, Inc, reports how a FlowSyn™ continuous flow reactor installed at Adesis Inc is assisting them in evaluating custom synthetic routes for compounds along with improving existing batch manufacturing processes.

The Adesis Flow Chemistry Group, led by Dr Hai Le, is already performing reactions using the Uniqsis FlowSyn for homogenous reactions along with a Gas Addition Module (GAM), for reactions involving high vapour pressure reactive gases like hydrogen and oxygen.

Dr Le said: “My group uses the Uniqsis FlowSyn for the evaluation of the best routes in terms of yield and economics for compounds of critical importance to our customers. Our approach is to evaluate hundreds of potential reaction pathways quickly and repeatably, always looking to provide the greatest value to our customers. Our ability to quickly identify the maximum value path is supported by the versatility of the Uniqsis FlowSyn family of products that enable tens of reactions per day that vary temperature, residence time and mole ratio by simply entering these parameters into a keypad and letting the automated FlowSyn system provide continuous product samples ready for analysis. In particular, the GAM allows for the rapid change-out to and from using reactive gases. No other tool on the market allows for this level of speed and versatility when evaluating gas-liquid reactions. The addition of the Uniqsis FlowSyn tool suite has enabled us to support the needs of our customers whose requirements for cost, quality and speed to market are of the utmost concern. Most recently, we successfully developed a critical flow process for a commercial-ready-chemical. The flow method doubles the overall yield, minimises stoichiometry of a starting material which require multiple synthetic steps to obtain, while decreasing by-product formation from 30% to 0.2%. This process can be scaled up to deliver hundreds of grams per day reproducibly.”

Dr Le added that the FlowSyn system has also been critically supportive of existing batch reactions because of its ability to perform a wide variety of exploratory reaction conditions so quickly. Adesis existing custom manufacturing operations benefit by knowing that they have the best set of reaction conditions. Another major consideration in obtaining the Uniqsis system was the support of Uniqsis USA Distributor, Sentinel Process Systems, Inc. “We are very impressed with the rapid and detailed support we have received from Sentinel. The fact that US support was available for the Uniqsis system in the USA was a major consideration in our decision to invest in the Uniqsis FlowSyn system.” Dr Le said, “Since our investment, the continued support that Sentinel provides has made us very comfortable with expanding our suite of flow chemistry initiatives.”

FlowSyn is a versatile automated flow chemistry system and can be configured with up to 4 pump channels with a choice of 10ml/min, or 50ml/min pump heads for higher scale applications. It can be programmed to run 10 sequential reactions that deposits reaction product in vials ready for instant analysis. It may also be configured with any combination of up to 4 individual heated/cooled reactor modules. By selecting from the HotCoil™ and HotChip™ heated reactor modules, and the Polar Bear Plus Flow™ and Polar Bear Plus GSM™ cryogenic modules (with an operating range from -40°C to 300°C) the FlowSyn offers unrivalled flexibility. The FlowSyn continuous flow reactor can also be integrated with the Uniqsis Flow-UV™ inline UV-VIS spectrophotometer to monitor steady state conditions in real time.

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK