-

Figure 1: New Knife Mill GRINDOMIX GM 200

Figure 1: New Knife Mill GRINDOMIX GM 200 -

Figure 2: The MyRETSCH web portal offers a wealth of product and application information

Figure 2: The MyRETSCH web portal offers a wealth of product and application information -

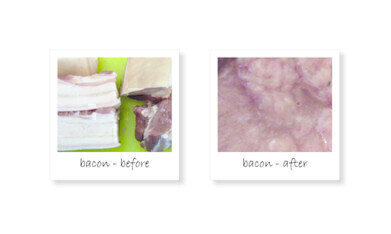

Figure 3: Bacon before and after complete homogenisation in the new GM 200

Figure 3: Bacon before and after complete homogenisation in the new GM 200 -

Figure 4: Kohlrabi before (left) homogenisation and after pre-cutting (middle) and fine grinding (right) in the new GM 200

Figure 4: Kohlrabi before (left) homogenisation and after pre-cutting (middle) and fine grinding (right) in the new GM 200 -

Figure 5: Sticky raisins before and after complete homogenisation in the new GM 200

Figure 5: Sticky raisins before and after complete homogenisation in the new GM 200

Laboratory Products

Perfect homogenisation of food samples with the new knife mill GRINDOMIX GM 200

Mar 14 2018

The diversity of foodstuffs with their often very different properties represents a challenge for food testing laboratories. The new Knife Mill GRINDOMIX GM 200 sets standards in food sample preparation. The cutting effect produced by the steel blades results in the perfect homogenisation of samples with high water, oil, sugar or fat content. The GM 200 - which accepts sample volumes up to 700 ml - has been completely revised and upgraded. This mill covers a wide application range from grainy food stuff such as rape seed, rice, soy beans or corn to fibrous or tough samples such as meat, fish, sticky candy or cheese.

New features improve homogenisation of difficult samples

Thanks to new features like the powerful 1000 W drive, the mill can homogenise even difficult samples like tough meat with skin or fibrous plants very quickly and efficiently without blockages or the need for more than two grinding steps. The innovative Boost function allows for a temporary speed increase to 14.000 min-1, providing extra power for the homogenisation of difficult samples in a very short time. The mill offers three different operation modes to optimise the homogenisation process regarding the material properties. Up to 8 programs can be stored for routine applications as well as 4 program sequences which is ideal to combine two grinding steps.

A wide selection of accessories allows for individual adaptation to application requirements. The grinding containers are available in steel, glass, polycarbonate, and polypropylene. A patented gravity lid reduces the sample volume during the grinding process, thus permitting thorough homogenisation of the entire sample. For samples with a high liquid content, a gravity lid with overflow channels is available. The so-called reduction lids reduce the container volume to 0.3 l or 0.5 l, thus submitting smaller sample volumes continuously to the grinding process. Beside the standard knife, a knife with serrated blades for tough samples like meat or a knife with pure titanium blades for heavy-metal free homogenisation are available.

MyRETSCH web portal

The GM 200 is the first mill to provide direct access to the new MyRETSCH web portal. This portal can be accessed by simply scanning the QR code in the user-friendly 4.3’’ touch display. It offers a wealth of information on the product itself, like operating manual or available accessories, but also application-specific documents. These include more than 80 grinding protocols as well as handling videos which demonstrate use of the mill step by step or ‘tips & tricks’ documents. This information helps the user to optimise the grinding process and achieve best possible results.

Application examples

Meat/Bacon/Fish with very tough or thick skin

Meat samples may be very tough, especially, if they contain large fatty parts. 450 g of meat were pre-cut manually to pieces of approximately 50 mm. Until now, complete homogenisation of such meat samples had to be carried out in 4-5 grinding steps with increasing speed to avoid blocking of the blades. In the new GM 200, however, the sample was fully homogenised in only two grinding steps thanks to the improved powerful 1000 W drive. Pre-cutting was performed at a revolution speed of 7000 min-1 for 10 seconds. The standard lid was used in this step, so that the large initial sample pieces had enough space to move inside the grinding container. The gravity lid was used in the fine grinding step at a revolution speed of 10,000 min-1 for 20 seconds as the lid automatically reduces the volume of the grinding chamber with decreasing sample volume. The use of the serrated blades knife increased the cutting efficiency. The Boost function with a temporary speed of 14.000 min-1 may be useful to homogenise the toughest parts of the sample.

Vegetables with low water content

Vegetables often contain moisture or even consist predominantly of water. In the latter case, complete homogenisation is facilitated, as sample pieces are too wet to stick on the walls of the grinding container where they no longer come into contact with the rotating knifes. This is not the case with samples like kohlrabi which have a lower water content. The sample pieces tend to stick on the wall of the grinding container, thus evading contact with the knife blades. A few sample pieces may remain in the mostly homogeneous sample, even if maximum speed was used. Using a specific lid like the gravity lid with overflow channels helps to improve the grinding effect, but full homogenisation is often achieved by adding water to the sample. 280 g kohlrabi was cut manually in four pieces. Grinding was performed in two steps. It is recommended to use a low speed of 2000 min-1 for the first 10 seconds. For fine grinding at 5000 min-1, 50 ml water was added to achieve a good homogeneity after 20 seconds. The gravity lid with overflow channels was used to ensure thorough homogenisation. The interval mode during the fine grinding step improves mixing of the sample and thus increases grinding efficiency.

Sticky samples like raisins, sweets, cheese

Sticky samples tend to agglomerate and stick on the knife blades or the walls of the grinding container. Thus, the degree of homogenisation can be rather low. The strong 1000 W power drive of the GM 200 now ensures that the blades do not get blocked even when homogenising e. g. 200 g of raisins at a revolution speed of 10,000 min-1 for 10 seconds in cutting mode. The reduction lid forces the sample against the blades, thus improving the degree of homogenisation.

Figure 5: Sticky raisins before and after complete homogenisation in the new GM 200

Conclusion

The new GRINDOMIX GM 200 is the perfect mill to homogenise dry, oily, fatty, soft and tough sample materials up to 700 ml - for analysis results with minimum standard deviation. Moreover, it is the first Retsch mill offering direct access via QR code to the MyRETSCH web portal with product- and application-specific information.

For larger quantities Retsch offers the GM 300 model with a grinding chamber volume of 5,000 ml.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 17 2024 Tokyo, Japan

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

.jpg)