Laboratory Products

Size is everything - Are you getting the true measurements of your particles?

Apr 04 2012

If you are involved in particle sizing, ask yourself “Am I measuring the true dimensions of my sample?”.

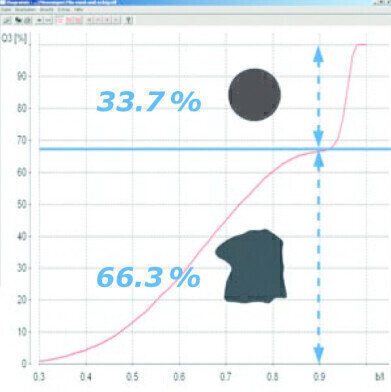

Many methods of particle sizing produce a single cumulative graph, which does not describe the true shape, or dimensions and distribution of particles. If you are using data of this kind, you may be basing your analyses on a false picture.

The solution

Dynamic Image Analysis

Dynamic Image Analysis is a method which recognises the real shape of particles, rather than making assumptions and generalisations that all particles are an equivalent spherical diameter.

What machine uses the Dynamic Image Analysis principle?

The Camsizer and Camsizer XT range from Retsch Technology are the forerunners in Dynamic Image Analysis – producing data which is meaningful, precise and shows a true picture of your sample. Many Retsch Technology Customers? have discovered wide variances in their analyses when conducting particle sizing procedures alongside other common methods. The Camsizer uses a unique, patented, digital Two-Camera system to measure solids from 30 µm to 30 mm. The result is a complete distribution of size and shape of your powder or granules and 100% compatible to those of sieve analysis.

To illustrate this principle, here is an overview of what measurements can be taken by a Camsizer:

• X_area

• XMa_max

• X_Femax

• Xc_max

• Xc_min

• X_length

• XFe_min

• XMa_min

• XMa_rec

• X_stretch

• Transparency

• Sphericity

• Convexity

What do these results mean?

If you are involved with particle sizing as part of a quality control, or research and development process, you can measure the real dimensions of your material.

How can I use Dynamic Image Analysis?

Many Retsch Technology customers use Dynamic Image analysis either as the sole, reliable method of particle sizing or alongside other methods such as sieving, laser diffraction, sedimentation, time of flight or electro-sensing zone. The Camsizer XT is suitable for finer samples from 1 µm to 3 mm and can be used to measure fine powders, fine particles which tend to agglomerate and particles within a liquid.

How can I start to get true, precise results?

Retsch Technology have a long history or successfully solving customer’s particle sizing needs. Retsch Technology can consult with you on your method, sample material, preparation, operation, analysis and instrumentation. This consultation can be conducted by email, phone or at our customer demonstration laboratory in West Yorkshire where your sample can be measured so you can view, in person, the real dimensions of the sample.

Contact Retsch Technology on 01924 221 076 or email technology@retsch.co.uk. To view the product video, download the brochure or to learn more about Digital Image Analysis go the Retsch Technology website.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

.jpg)