-

Fine Cut Group have been providing label solutions for 40 years.

Fine Cut Group have been providing label solutions for 40 years. -

The On-demand’ print system allows to print onto labels direct using a predefined template.

The On-demand’ print system allows to print onto labels direct using a predefined template.

Laboratory Products

Durable Laboratory Labels: Surviving the Most Extreme Environments

Jan 13 2022

Fine Cut Group have worked side by side with the NHS, Government bodies and private laboratories providing label solutions for 40 years. Leading the way with durable, innovative medical labels and identification and marking products for the medical industry, including medical device labelling, clinical trial / sample identification and pharmaceutical labelling requirements.

Producing durable labels and overlays for a broad spectrum of hospital, laboratory and pharmaceutical equipment, and catering for both short and long runs, the company are able to provide recommendations for a variety of medical label applications, ranging from patient monitoring equipment to analytical instruments.

Durable and permanent are two of the main criteria required when sourcing labels for the identification of laboratory cryogenic samples. Fine Cut’s specialist ‘Cryo’ polyester meets this requirement and also has a specially formulated adhesive that allows for long term bonding when used on plastic cryogenic storage pots and tubes, which can be directly immersed in liquid nitrogen at -196°C without risk of de-lamination.

Resistance to chemicals and solvents within the laboratory environment is a key element to maintaining full batch and sample traceability. Offering enhanced durability against a wide range of contaminants including Acetone, IPA, Toluene, Xylene and DMSO. The Integrity of the data on a label is critical to the handling and analysing of the sample, and therefore the ability to survive in the harshest of environments becomes a vanguard for the labelling of all samples.

On Demand Print Flexibility

Replace handwritten data on sample tubes with durable polyester labels suitable for ‘in-lab’ printing via a standard desktop laser printer or dedicated thermal transfer printer. Handwriting directly onto tubes or labels may be convenient but in the long run it can be unreliable, prone to smudging and difficult to read, thus being ineffective and inefficient. Adding data via the ‘print-in-lab’ process will allow you to achieve enhanced readability and the option of also introducing barcodes or 2D codes onto your labels for quick scanning options.

Printing via the ‘print-in-lab’ process will also enable you to print direct from excel or via your LIMS (Laboratory information Management system) maintaining data formatting and eliminating human input error. This is particularly important to retain measured quality procedures for good laboratory practice (GLP), external accreditation and auditing purposes, whilst maintaining sample integrity.

In house printed labels also enable you to establish and control an agreed format for all samples ensuring each sample is identified using the same process (label) and chosen typeface, so they are easily recognisable and can be used during the whole laboratory sample life. This is particularly useful when large volume batches are being processed.

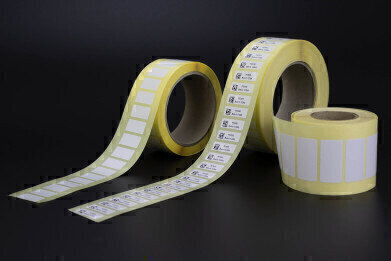

Label materials are available in both roll and sheet format and feature a permanent acrylic adhesive suitable for use in extreme temperatures (rating -196C to +155C) so very versatile for lab storage. Excellent for identifying sample vials, collection tubes and associated plasticware / glassware used within the laboratory that requires storage within the freezer or fridge.

Laboratory Labelling Case Study

A major NHS hospital contacted Fine Cut to help them find a solution to an issue within a busy laboratory. Staff at the unit were struggling to read batch and date information on patient labels used on sample tubes with a 100% accuracy owing to different handwriting styles and formats being used. To compound the issue there were also instances where the patient data on the sample tubes was smudged making the data illegible and the sample data unusable

Team members at the laboratory acknowledged that this issue could not be repeated and action to find a remedy was of great importance. One of Fine Cut’s technical team contacted the laboratory to determine the best course of action to take and recommend a solution that would improve both the readability of the sample data and the durability of the print.

To improve the readability and efficiency of the tube data it was recommended that the laboratory adopt an ‘On-demand’ print system that would allow them to print onto labels direct using a predefined template. This would allow all of the users to print samples ‘in- house’ to a high standard and an agreed format that would be easy to read. The unit also introduced barcodes and 2D codes onto the labels to offer accurate and efficient scanning of samples thus improving traceability within the unit.

The new print process offers the unit greater durability and enhanced flexibility for all of their label printing and enabled the technical team to recommend using a polyester label material capable of being used in harsh environments with the ability to withstand freezer storage and resistance to solvents, moisture and handling. This improvement eliminated the need to handwrite direct onto tubes and labels and also resolved the issue of the smudging of data.

If you wish to discuss a project in more detail - please contact the sales team today

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)