Laboratory Products

On-Line Particle Sizer helps Manufacturer Attain 100% Testing of Coffee Makers

May 31 2012

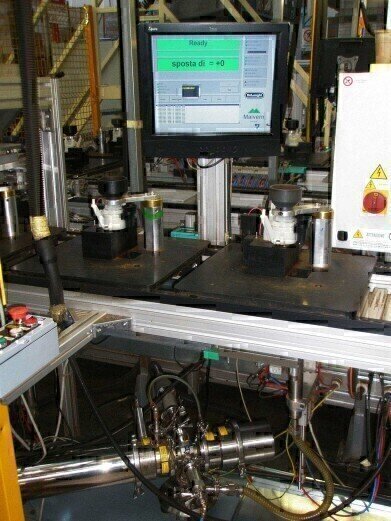

Renowned globally for the quality of its coffee makers, manufacturer De'Longhi has transformed QC processes for grinders at its manufacturing facility in Mignagola di Carbonera, using the Insitec on-line particle size analyser from Malvern Instruments. The Malvern applications team worked closely with engineers at De'Longhi to develop a fully automated solution that supports the target of achieving 100% testing, of every element, of each ‘bean to cup’ coffee maker. The Insitec solution is easy to use, extremely reliable and robust, and testing is complete in just a few seconds. Three systems are now in continuous operation on three parallel assembly lines.

De'Longhi commented: “Because we wanted to test every single grinder that comes off the assembly line, measurement speed was critically important to us. The interface we’ve developed guides the assembly line worker as to any corrective action required to ensure that this performance meets our defined specification. The results are tagged to the specific grinder so we have an audit trail for every single coffee maker that leaves the site.”

‘Bean to cup’ coffee makers incorporate an integral grinder, whose performance has a defining influence on the taste of the finished cup of coffee. At De'Longhi, grinder set-up is assessed, on the assembly line, by analysing the particle size of freshly ground coffee beans. While the essential basis of the solution is particle size distribution data, the system has been engineered to provide operatives with simple pass/fail information. Out-of-specification performance is rectified by turning a gear wheel in either direction to move the grinding surfaces closer or further apart, the Insitec interface providing direct instructions as to what action to take.

The Insitec is a laser diffraction particle size analyser for in- or on-line use. Measuring up to four complete size distributions every second it provides real-time data that effectively tracks even the most rapidly changing processes. Insitec technology is designed specifically for the process environment and is suitable for both wet and dry streams with particles in the size range 0.1 to 2500 microns.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

May 21 2024 Lagos, Nigeria

May 22 2024 Basel, Switzerland

Scientific Laboratory Show & Conference 2024

May 22 2024 Nottingham, UK

May 23 2024 Beijing, China

May 28 2024 Tel Aviv, Israel

.jpg)