-

Biopharma Group’s systematic approach in freeze drying.

Biopharma Group’s systematic approach in freeze drying.

Laboratory Products

A Systematic Approach to Freeze Drying Food

Aug 07 2019

Water is generally the main ‘ingredient’ in food and has a considerable impact on both physico-chemical and mechanical properties, which constantly change during storage. The product shelf life is limited by biological activity of microorganisms and water deeply affects it. Bacteria and moulds easily grow and proliferate in humid conditions, resulting in quicker spoilage and organoleptic degradation. However, not all water present in food has the same influence on the growth of microorganisms. In fact, interaction of water with the material structure can be different: part of it strongly interacts with the material matrix in a dynamic equilibrium, while the remaining, which is the majority, becomes more available for physical, chemical and microbiological reactions.

In order to reduce the water content and activity, drying is carried out. This process will have an impact on the final food attributes and quality and, therefore, it should be performed rationally.

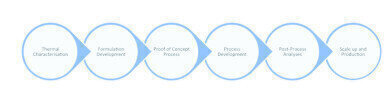

Biopharma has recently expanded their facilities to allow for food freeze drying, introducing services built on a quality by design (QbD) approach that aims to assist in achieving the customer requirements in terms of shelf life, appearance and physico-chemical properties. An initial characterisation of the thermal behaviour of the pre-lyophilised product is essential in order to design a tailored drying cycle and make the product more suitable for the process. Without it, the risk is to use a freeze drying process that dries the product, but not in a safe and efficient way, affecting irreversibly the quality. Technologies such as freeze drying microscopy (Lyostat), electrical impedance analysis (Lyotherm) and differential scanning calorimetry (DSC) are typically used to fully understand the food thermal behaviour.

Knowing the thermal stability of the product allows to prevent deleterious events such as boiling and ‘puffing’, shrinkage and collapse, clump formation, increased density, slowed sublimation kinetics, slowed rehydration, colour change and nutrient loss. After this thermal characterisation, food can be reformulated or treated with hypertonic solutions to improve the final appearance after drying as well as the mechanical and chemical properties. Finally, after the proof of concept and/or the process optimisation, the dried material is evaluated with post-process analyses.

More information online: www.biopharma.co.uk

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

.jpg)