Laboratory Products

Data processing in drying process.

Apr 04 2012

RADWAG moisture analyzers MAX series are instruments, that gained reputation among multiple European users. The device is designed to meet the requirements of those users, who expect measuring accuracy of d=0,1 mg and drying accuracy 0,0001 %. The MAX series provides four drying modes each adjusted to specific application of the device.

• Standard for regular drying process, recommended for approximately 90 % of drying procedures

• Fast drying process, initially with temperature exceeded by 30 %, then shifting to the set temperature, for shortening drying process time.

• Step enables setting phases of drying process, each with set temperature and finish mode. On completing the following step is activated. The step mode is useful for drying samples containing a large amount of water.

• Mild useful for samples requiring fairly slow increase of drying temperature. Resulting in mild humidity evaporation

Additionally, the MAX series provides setting custom parameters of drying process and finish criteria, etc. Measuring data, and other parameters are displayed on a backlit graphic display ensuring excellent reading.

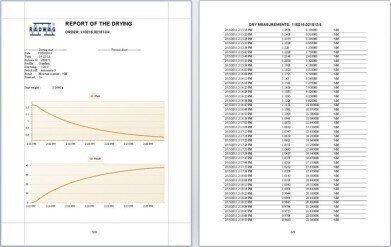

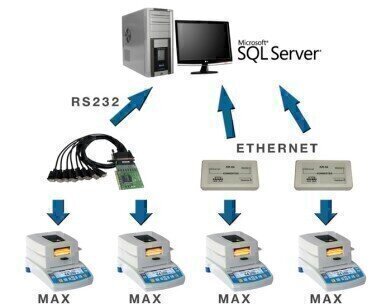

For the purpose of creating a complete drying system, and simplification of data processing, RADWAG offers a network management module, E2R System Moisture Analyzer, i.e. software for remote control over measurement process performed on multiple Radwag moisture analyzers connected through Ethernet. The software is based on MS SQL computer databases, and processed data are easily used to form graphs and reports of weighing process.

The software, is an indispensable tool in places where MAX series is used, i.e. in laboratories and production plants where control, archiving and real-time analysis of drying data is required. The E2R Moisture Analyzer is a perfect application for systematic monitoring of production process.

E2R Moisture Analyzer – functions:

• Reading data from moisture analyzers and saving them in MS SQL database:

• On-line operation allows real-time monitoring of drying processes in progress, from any PC,

• Support and simultaneous monitoring of 16 moisture analyzers;

• Automatic initiation of connection between moisture analyzers with a database after PC start up (working as OS service);

• Previewing drying process status, including the following:

o Mass in grams,

o One of the results:

(moisture content %M, dry content %D, moisture/dry %R, mass in grams, percentage graph %M),

o Temperature,

o Drying order status,

o Date and time of drying process initiation,

o Drying time,

o Date and time of recording measurements into database,

and

o Initial and final mass;

o Final result;

o Drying profile;

o Temperature of the drying order;

o Type of order accomplishing.

• On-line status view of measurements and drying results;

• Generating on-line graphs related to drying time;

• Access to reports generated by moisture analyzers;

• Moisture analyzers can be connected through mulitport RS 232 card or Ethernet/RS232 converter within Ethernet network;

• Data and records filters, grouping and sorting of orders and single measurement;

• Records of reports and graphs:

o Selected order record;

o Overall comparison of results;

• Defining different access levels for users;

• Multilanguage interface of each system component;

• Graphical interface customization: individual reports and graphs templates;

For more information see: www.radwag.com.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

May 21 2024 Lagos, Nigeria

May 22 2024 Basel, Switzerland

.jpg)