-

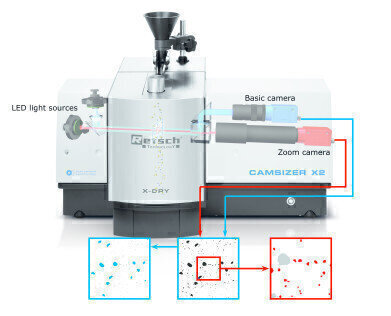

Figure 1: Optical design of the CAMSIZER X2.

Figure 1: Optical design of the CAMSIZER X2. -

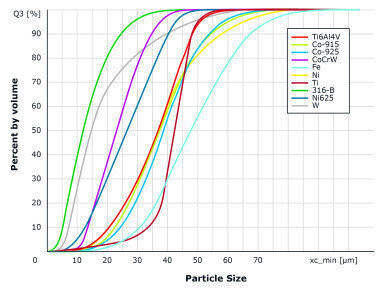

Figure 2: CAMSIZER X2 size measurement of ten different metal powders. Powder 316-B is the finest with a median of 12µm, the Ti powder is characterised by a very narrow distribution (all particles are very similar in size)

Figure 2: CAMSIZER X2 size measurement of ten different metal powders. Powder 316-B is the finest with a median of 12µm, the Ti powder is characterised by a very narrow distribution (all particles are very similar in size) -

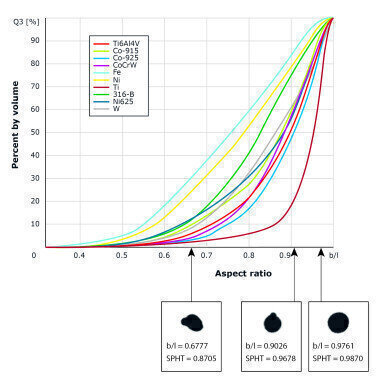

Figure 3: Comparison of the shape parameter ‘aspect ratio’ for the ten metal powder samples. The shape diagram shows that the titanium powder is most compact, whereas the iron powder particles are the most elongated. The insert shows typical images of steel particles with different shape (satellites, elliptical droplets), and the calculated roundness (SPHT) and elongation (b/l).

Figure 3: Comparison of the shape parameter ‘aspect ratio’ for the ten metal powder samples. The shape diagram shows that the titanium powder is most compact, whereas the iron powder particles are the most elongated. The insert shows typical images of steel particles with different shape (satellites, elliptical droplets), and the calculated roundness (SPHT) and elongation (b/l).

Laboratory Products

The new generation of particle characterisation – Image Analysis with the CAMSIZER X2

Mar 10 2017

Particle characterisation by Dynamic Image Analysis (DIA) has become increasingly popular in recent years. This technique delivers very accurate particle size distributions in a very short time, is virtually maintenance-free and, unlike other methods like sieve analysis or laser diffraction, provides particle shape information. The CAMSIZER X2 is the latest generation of Retsch Technology’s most versatile digital image analyser. It measures granulates, powders and suspensions in a size range from 0.8 µm to 8 mm. Typical applications include pharmaceuticals, foodstuff, chemicals, metal powders, polymers, raw materials like ores, coal or sand, and many more.

Wide measurement range – effective dispersion

To achieve excellent measurement results for fine particles, efficient dispersion and powerful high-resolution optics are essential. The CAMSIZER X2 offers three alternative options for dispersion: air-jet dispersion of fine powders, free-fall measurement of fragile particles, and a wet unit for suspensions. The instrument can be adapted to the required mode of operation within a few seconds.

The patented optical system features two ultra-bright LED light sources and two high resolution CCD cameras. This dual-camera technology ensures that one camera detects fine particles with great accuracy whereas the other camera will focus on the large particles. Thus, the CAMSIZER X2 achieves a wider measurement range than any other image analyser. With more than 300 images analysed per second, the result is based on the characterisation of hundreds of thousands or even millions of individual particles. One measurement typically takes only 1 to 3 minutes.

Simultaneous analysis of size and shape

The application example shows CAMSIZER X2 measurement data of several metal powder samples in a size range from 1 µm to 100 µm such as are used in different powder metallurgical processes. The results show variations in mean size as well as width of distribution (Figure 2). Not only does the CAMSIZER X2 determine the size distribution, it also measures the particle shape. Figure 3 shows the result for the aspect ratio (particle width divided by particle length) for every sample. The aspect ratio of round, isometric particles is close to 1, the corresponding curve will plot on the right side of the diagram. Shape analysis of the metal powders is important to judge the quality of the production and the suitability for the subsequent processing. Irrespective of the differences in chemistry, density, size and shape, all samples can be reliably analysed with the CAMSIZER X2.

What you see is what you get

Only image analysis provides a clear and unambiguous definition of particle size and shape. With every measurement, a wealth of information on particle properties is obtained: Particle length, width, equal area diameter, aspect ratio, symmetry, roundness, etc. The CAMSIZER X2 matches and even outperforms any other method of particle characterisation in the size range from 0.8 µm – 8mm.

Conclusion

Dynamic Image Analysis with the CAMSIZER X2 provides all relevant data on particle size and shape. Compared to other techniques like laser diffraction or (electron or optical) microscopy, the measurement data are based on a larger number of particles and are therefore statistically more relevant and have better repeatability. One measurement only takes 1 to 3 minutes, allowing for high sample throughput and continuous quality control. The CAMSIZER X2 is therefore suited for accurate and reproducible characterisation of a great variety of different materials.

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)

.jpg)