-

-

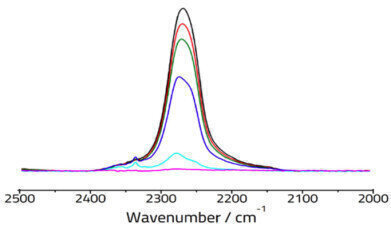

Decay of NCO in absorbance mode over time in a two-pot packaging adhesive at standard mix ratio.

Decay of NCO in absorbance mode over time in a two-pot packaging adhesive at standard mix ratio. -

Mass Spectrometry & Spectroscopy

Solvent Free Packaging Adhesive Application Note

Oct 29 2020

Did you know that your crisps packets, drink pouches or even dog food packaging are made of many polymer layers stuck together by glue to optimise mechanical and barrier properties? Conventional Lamination Adhesives used in multi-layered flexible packaging are commonly a product of solvent-based or solvent free two-pot systems that undergo the following reaction:

Polyol (-OH) + Isocyanate (-N=C=O)à Polyurethane lamination adhesive (-NHCOO-)

The packaging industry often use FTIR to screen test the decay rate of isocyanate (NCO) in a freshly applied adhesive because unreacted aromatic NCO molecules can migrate through laminated packaging into food to react with water molecules, generating carcinogenic primary aromatic amines that are harmful to humans and pets alike. By measuring the reduction of NCO absorbance peak height over time at ~2270-2250 cm-1, this decay serves as an indicator for adhesive curing speed and food packaging safety. The spectra were taken over time from the same solvent free adhesive on a single Arrow slide.

Multiple Arrow Slides can also be used to compare the curing speed of different adhesives at the same time. Adhesive curing speed has many variables like OH to NCO mix ratio, curing temperature, relative humidity, the crosslink-ability of starting components and the reactivity of the aromatic NCO component amongst other factors. Sometimes the curing process can take days or even weeks, so to have just one conventional crystal ATR puck occupied for prolonged periods might not be coolest idea. High volume batch sampling using Arrow consumable ATR Slides can really save you time and speed up your work to make your organisation more competitive. Furthermore, once the polyurethane product is formed on your crystal, it could be difficult to remove, and you might run the risk of damaging a relatively more expensive crystal puck; after all glue is designed to stick. So, the next time you test a sticky adhesive, varnish, paint, ink, or coating, why not give the Arrow a go?

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)