-

The variable Speed Rotor Mill PULVERISETTE 14 classic line.

The variable Speed Rotor Mill PULVERISETTE 14 classic line. -

The Fritsch high-performance Cyclone separator.

The Fritsch high-performance Cyclone separator. -

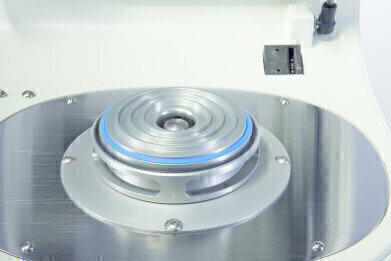

Efficient air cooling of the rotor.

Efficient air cooling of the rotor. -

The Fritsch small volume Cyclone separator.

The Fritsch small volume Cyclone separator.

Laboratory Products

Variable Speed Rotor Mill: Increase your Sample Prep Efficiency

Aug 23 2021

One mill, many possibilities

The Fritsch Variable Speed Rotor Mill PULVERISETTE 14 classic line is ideal for fast, effective comminution of soft to medium-hard, brittle and fibrous materials as well as temperature-sensitive samples - proven worldwide for the use in trace analysis.

The motor speed can be varied between 6,000 and 20,000 rpm in increments of one-thousand, making it possible to adapt the mill to each specific application. An automatic speed compensation feature ensures the most appropriate grinding to the specific comminution behaviour of the sample. At the same time, the fast, effective grinding through the efficient air routing inside the PULVERISETTE 14 classic line significantly reduces the thermal strain on the sample.

Efficient cooling

The ingenious air routing of the PULVERISETTE 14 classic line ensures a constant airflow to cool the rotor, all motor components and the grinding material in the collecting vessel. Simultaneously, a large fan blows the cooling air into the instrument through a foam particle filter, creating positive pressure that prevents the penetration of dirt particles from the ambient air.

Temperature-gentle fine grinding

In combination with the Fritsch Cyclone separators, the PULVERISETTE 14 classic line is ideal for ultra-fine grinding of temperature-sensitive materials and for smooth pre-crushing and fine-grinding of hard-brittle to soft samples, fatty or samples with residual moisture. The compact Fritsch small volume Cyclone separator made of plastic can be completely dismounted and cleaned in a dishwasher. The comminuted sample is collected in a screwed-on sample glass. The small volume Cyclone separator can also be used with the supplied fine-dust filter 80-100 µm for passive utilisation or combined with the exhaust system.

Of particular use to the analytical sector and the food and pharmaceutical industry, the Fritsch high-performance cyclone, completely made out of stainless steel 304, is indispensable in combination with the exhaust system.

The efficient air routing inside the PULVERISETTE 14 classic line and the powerful air vortex within the Fritsch Cyclone cools the sample during grinding, reduces the thermal load of the sample, minimises clogging of the sieve rings while simultaneously increasing the throughput significantly. Cleaning of the mill itself is reduced to a minimum. The airflow inside the Fritsch Cyclone leads the ground sample directly into the collecting vessel. This type of sample discharge is the most convenient, as the ground material is drawn directly into the glass bottle where it can be transported, stored and easily removed for analysis.

Comminution with liquid nitrogen

Extremely difficult to grind or acutely temperature-sensitive samples like styrene, polyester, synthetic resins, foils, PVC, PP and PE can be embrittled by adding liquid nitrogen and afterwards ground with the PULVERISETTE 14 classic line.

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 28 2024 Montreal, Quebec, Canada

May 05 2024 Seville, Spain

InformEx Zone at CPhl North America

May 07 2024 Pennsylvania, PA, USA

May 14 2024 Oklahoma City, OK, USA

May 15 2024 Birmingham, UK

.jpg)