Laboratory Products

Knife Mill Delivers Fast Representative Samples for Reliable Analysis

Jan 06 2020

The Knife Mill PULVERISETTE 11 from Fritsch provides a homogeneous sample in a very short time and is ideal for a wide range of different materials, regardless of whether the sample is dry, moist, soft, medium-hard, fibrous or oily. It is the perfect instrument for sample preparation in the fields of foodstuffs or animal feed testing, agriculture and forestry, biology, pharmaceuticals and chemistry.

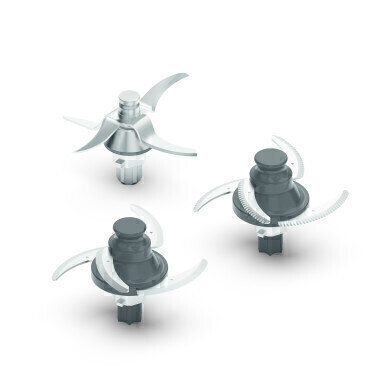

The standard knife made of stainless steel can be used for comminution of nearly all materials due to its four blades and a well-conceived geometry. For comminution of brittle, hard samples the stainless steel sickle knife is recommended.

In addition to the grinding vessel made of scratch-resistant Polycarbonate, a stainless steel 316L grinding vessel for cryogenic comminution and for grinding harder sample materials is available. Alternatively, a glass grinding vessel for food-safe analysis and for verification of polymers is available. For grinding oily samples and for BPA-free sample preparation, the Eastman Tritan Copolyester grinding vessel is recommended.

The freely adjustable Vario-Lid system can be used to reduce the grinding chamber volume down to 0.54 litre and to manually compress and loosen up the sample material at the beginning and at any time during comminution.

The grinding vessel, lid and knife of the PULVERISETTE 11 can be cleaned in a dishwasher. Depending on the version, all parts which come into contact with the sample materials such as grinding vessel, lid and knife are autoclavable.

Difficult to grind samples such as gummi bears, chocolate or plastic toys can be embrittled with liquid nitrogen for comminution directly in the stainless steel 316L grinding vessel. The sample material remains 100% cold. Just select the special lid with the easily exchangeable single-use sieve insert.

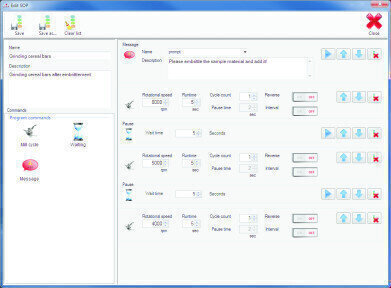

The PULVERISETTE 11 allows users to program and save up to 20 Standard Operating Procedures (SOPs). In each SOP you can save up to 15 grinding sequences.

All saved SOPs can be uploaded, exchanged and saved with the free SOP editor by laptop via the integrated USB interface. Simply download the SOP Editor at www.fritsch.de/p-11/sop.

With the software P-11Control, the mill can be controlled via the integrated USB port. SOPs can be edited, saved and managed directly on the connected laptop via drag & drop. Reversion-proof grinding reports can be created, archived quickly and easily with the integrated report generator.

More information online

Digital Edition

Lab Asia 31.2 April 2024

April 2024

In This Edition Chromatography Articles - Approaches to troubleshooting an SPE method for the analysis of oligonucleotides (pt i) - High-precision liquid flow processes demand full fluidic c...

View all digital editions

Events

Apr 22 2024 Marrakech, Morroco

Making Pharmaceuticals Exhibition & Conference

Apr 23 2024 Coventry, UK

Apr 23 2024 Kintex, South Korea

Apr 23 2024 Seoul, South Korea

Apr 24 2024 Jakarta, Indonesia

.jpg)

.jpg)